How it works

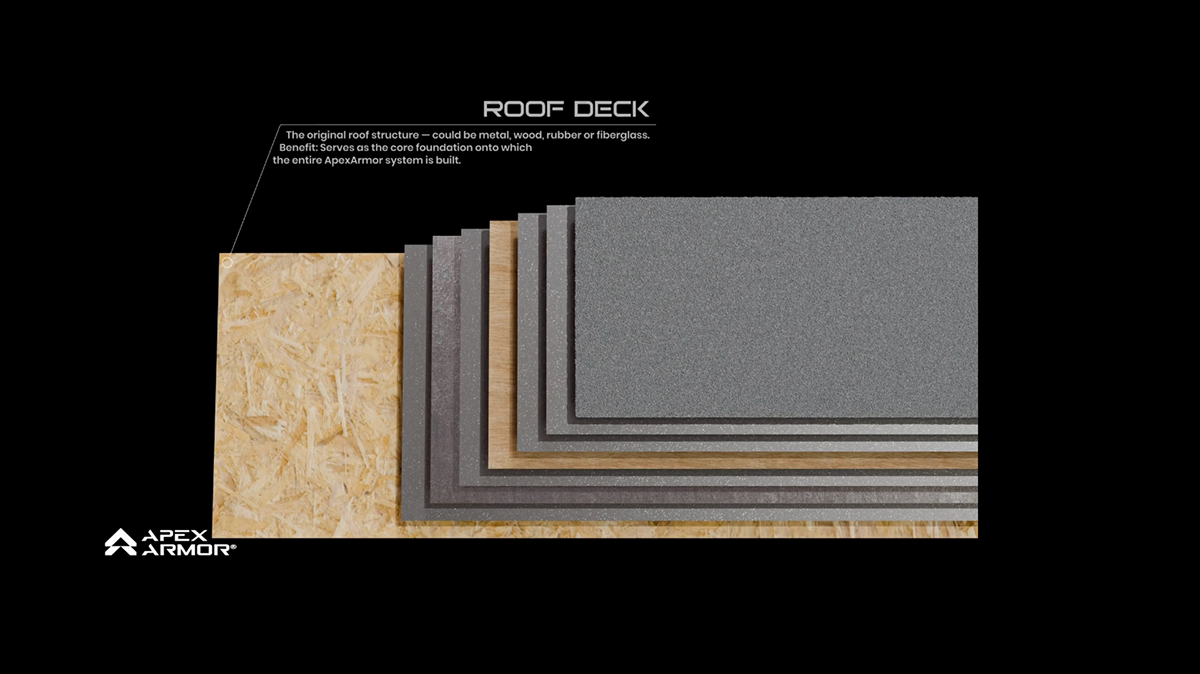

ApexArmor is unlike any Spray-On Roof System on the market. By fusing our ultra-flexible proprietary Aluminized Hybrid Polyurea we’ve engineered the most advanced heat-rejecting RV and trailer roofing system on the market — a breakthrough solution that is currently patent pending.

ApexArmor Installation Process

Component Removal:

IMPORTANT NOTES:

Surface Preparation:

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

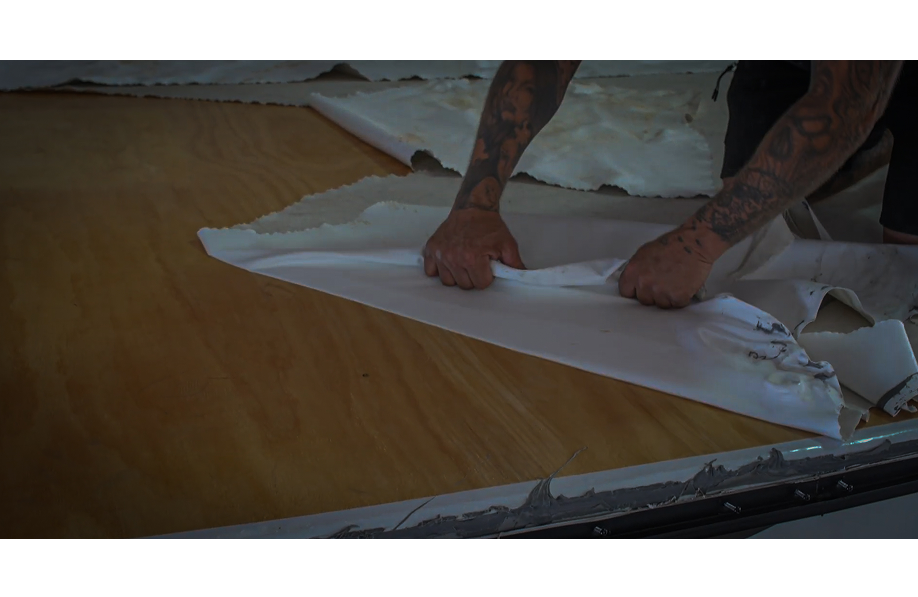

Overlayment Installation:

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

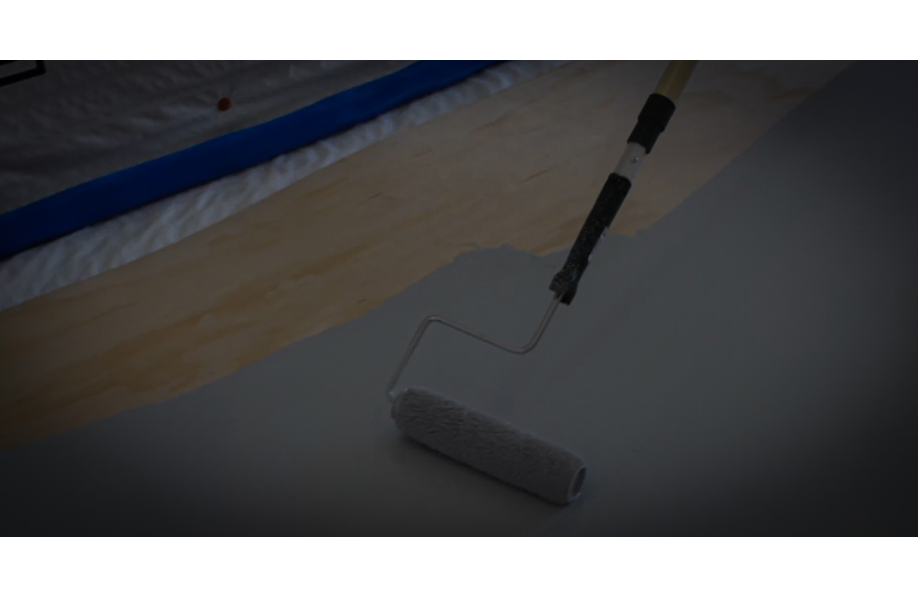

Adhesion Priming:

A specialized bonding primer is applied to maximize adhesion between the roof surface and the ApexArmor base layer. This step ensures that the spray-applied polyurea chemically bonds and permanently integrates with the prepared substrate.

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

Protective Masking:

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

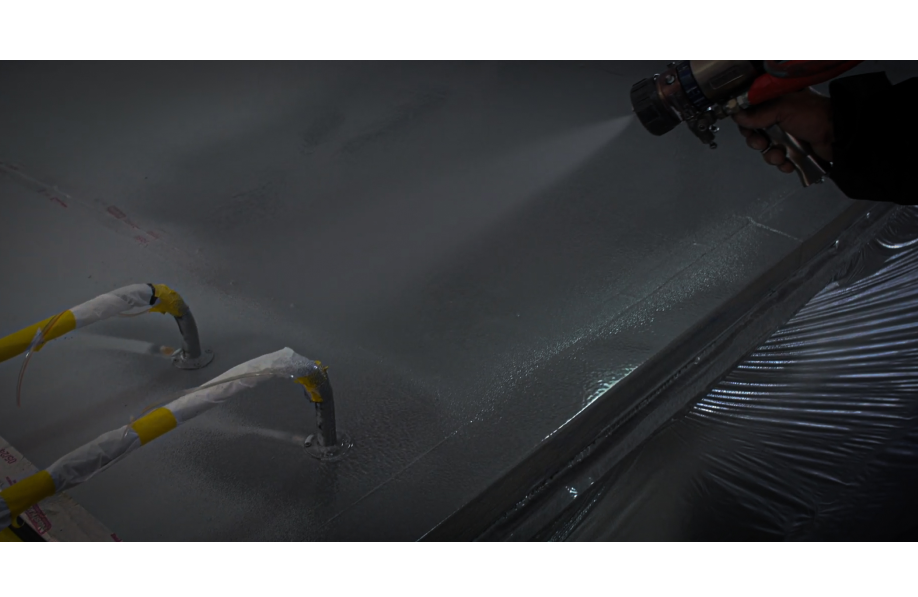

Base Layer Application:

The first layer of ApexArmor’s hybrid polyurea is spray-applied evenly across the roof. This creates a seamless, durable foundation that is impact-resistant and waterproof.

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

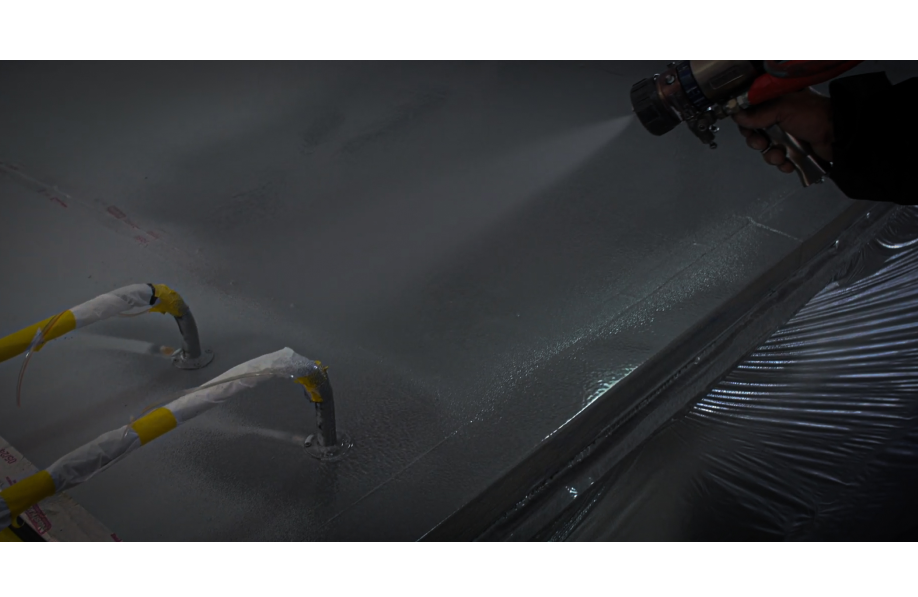

2nd Layer Application

The second layer of ApexArmor’s hybrid polyurea is spray-applied evenly across the roof.

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

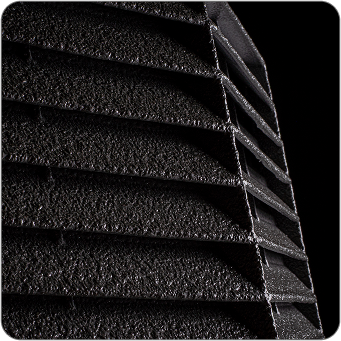

Safety Texture Coating:

A final safety-texture layer can be applied to improve traction and slip resistance. This is especially valuable for RV owners who may need to walk on the roof for maintenance, cleaning, or solar panel adjustments.

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

Optional Enhancements:

Customers can choose from various custom add-ons, such as:

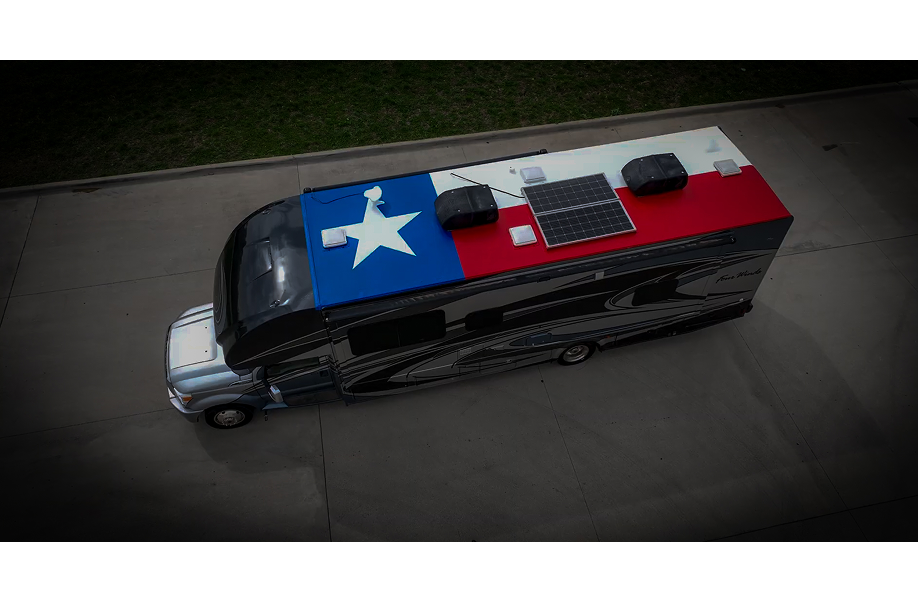

- Color customization

- Extra-thick applications for extreme durability

- Integrated graphics or patterns

- Component coating for extending the life of roof mounted components

IMPORTANT NOTES:

Apexarmor can be applied to metal, fiberglass, wood, rubber and some plastics with proper preparation.

Your A/Cs are still easy to service or replace – remove the 4 standard installation bolts and the A/C can be removed!

STEPS OF SERVICE

STEP

Contact an installer to begin the process and get connected with a certified roofing professional in your area.

STEP

The installer will perform a free on-site inspection of your roof—no need to move your unit or make special arrangements.

STEP

If the installer finds damage, they’ll assist you with filing an insurance claim so the cost of your roof is fully covered.

STEP

If no damage is found, you can pay out of pocket. Installer pricing is competitive and often beats written roof coating estimates.

STEP

Once everything is approved, your unit will be scheduled and brought into a service bay when the installation is ready to begin.

STEP

The ApexArmor roof installation process is efficient, typically taking just 2–3 business days to complete from start to finish.

Repair Process Overview

We assess the damage, approve the estimate, schedule service, complete repairs, test for quality, and return your unit ready to use.

Initial Contact & Repair Assessment

Customer contacts the repair facility; repair needs are discussed and established.

Insurance Claim Setup (if applicable)

If repairs require an insurance claim, an inspection date is scheduled.

Onsite Inspection (if needed)

A free onsite inspection is completed at your location. Note: For minor damages, photos or videos can be submitted instead for an initial estimate.

Estimate Preparation & Approval

A detailed estimate is prepared and submitted for approval by the customer or insurance provider.

Service Queue Placement

Once funds are secured, the unit is placed in the service queue.

Repair Date Scheduling

The repair date is confirmed and scheduled.

Customization & Final Details Discussion

Customer and repair facility review any customizations, specific requests, or upgrade options.

Unit Drop-Off or Pick-Up

The unit is either delivered to the facility by the customer or picked up by the repair team.

Service Check-In

Upon arrival, the unit is checked in, and all special requests are reviewed by the service team.

Repair & Service Work

The unit is moved into the service bay, where repairs and all customer requests are completed.

Quality Control & Water Testing

Final quality checks are performed, including a water test, to ensure all work meets the highest standards.

See why people choose ApexArmor over the rest

Scroll horizontally to explore all features →

Roofs$175–$200per LN FT

Roofs $190–$300per LN FT

On Roofs$190–$300per LN FT

Professional Installation You Can Trust

Whether you’re replacing a damaged roof, upgrading for heat rejection, or protecting your investment for the long haul, our installers are ready to deliver:

Uncompromising Roof Replacement

Advanced Heat Rejection

Our proprietary Aluminized Hybrid Polyurea keeps your RV cooler by reflecting heat and reducing energy costs.

Precision Installation

Trusted Local Service

Our network of installers provides transparent, reliable service you can count on.

Lifetime Warranty

Guaranteed durability and transferability increase your RV’s value.

Permanent

Leak-proof for life. This is the last roof your RV will need.

Maintenance Free

No more roof seals ever again, which means no more messy caulking.

Stronger

Designed to last a lifetime and won’t bubble, crack or puncture.

Watertight

100% seamless coating that forms a watertight seal around any gaps, protrusions, and bolts.

Paintable

Fully paintable and can be painted to match the exterior color of your unit.

Saves Money

Reduces your insurance premium. Saves approximately $500 a year in roof sealant removal and replacement costs.

Insulated

Superior UV protection engineered to reduce heat absorption by up to 20%. Keeps you and your crew cooler.

Choose Your Color